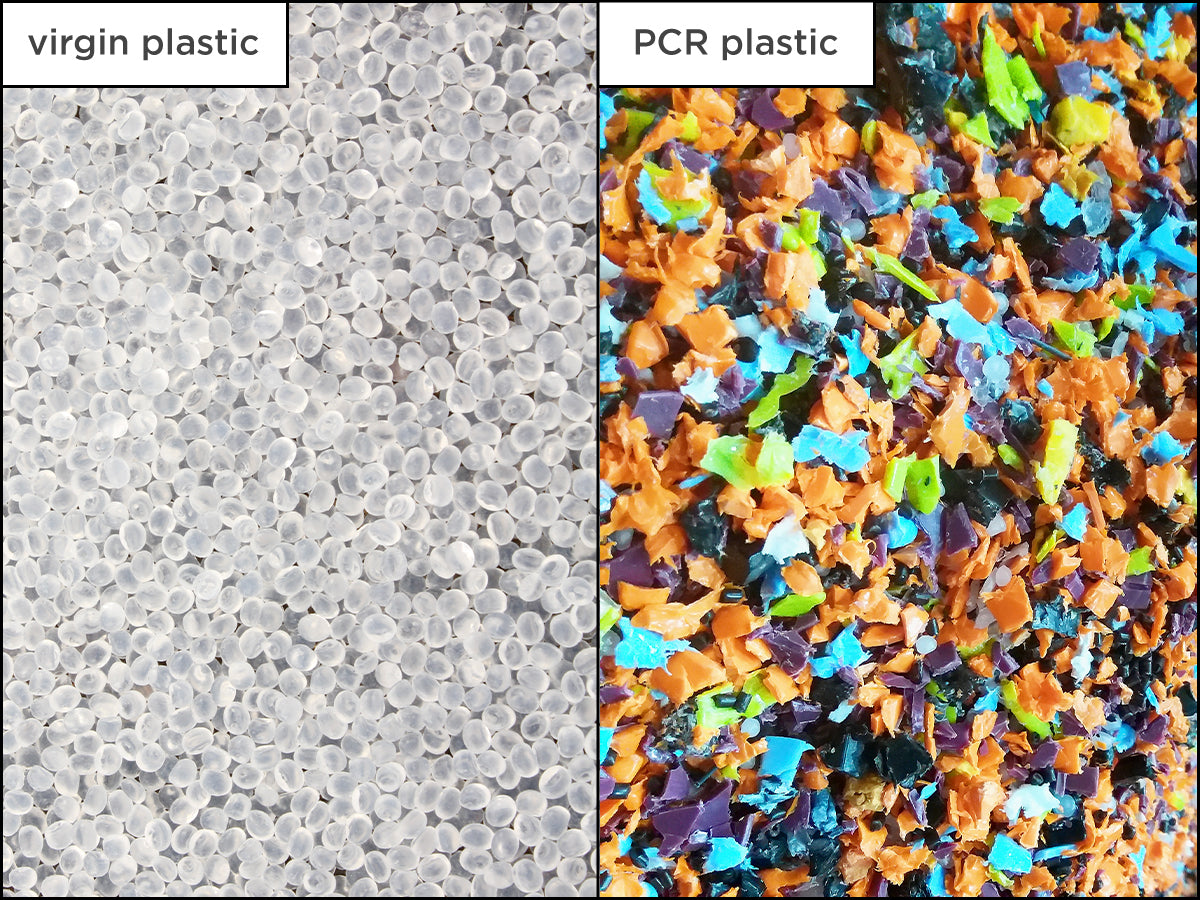

Plastics are a large part of everyday life and provide a wide range of benefits due to their strength, durability, variety of usage, and corrosion-resistant nature. However, it's become increasingly clear that plastic disposal poses issues to wildlife, human health, and the environment. Endeavors to prolong the life cycle of plastics are on the rise, including recycling previously used plastics to give them new life. Let’s look at the difference between new, unused plastics (referred to as virgin plastic) and recycled plastics, made from Post Consumer Recycled, or PCR, material.

What is Virgin Plastic?

Virgin plastic is new, unused plastic material created from resin produced from natural gas or crude oil. These plastics have not been blended with scrap, waste, or previously used material. They often provide a higher quality of material, including durability and consistency, and are currently easier to source.

What is PCR?

PCR stands for Post Consumer Recycled material and refers to plastics that have been recycled after their initial product life cycle and made into a new product. There are several types of PCR on the market, including high-density polyethylene (HDPE), polyethylene terephthalate (PET), and polypropylene (PP).

Why choose one over the other?

While PCR helps to extend the life cycle of many plastics, reducing the potential accumulation of plastic waste in the environment, there are a few challenges to using them. Recycling plastic requires high levels of cleaning and sorting to produce usable PCR resin, and unfortunately, many of the plastics that are sent to recycling centers don’t get recycled due to contamination. Those that do get recycled don’t always get sorted properly, so the resulting resin can lack the integrity of virgin plastics. The more times plastic is recycled, the more the quality degrades, which affects both durability and performance. All of this can make sourcing 100% PCR materials difficult, costly, and potentially unreliable.

Our approach:

At Briogeo, we make every effort to create and package our products as sustainably as we can, without compromising the integrity of the product, package, or user experience. With that in mind, we currently use a minimum of 30% post-consumer resin in our HDPE (high-density polyethylene) bottles. Where possible, while maintaining the integrity of the product packaging, we use 100% PCR material! With new innovations happening every day, both in the recycling industry and in materials manufacturing, we’re confident that we’ll continue to be able to provide better, more sustainable products as we move forward.